Products

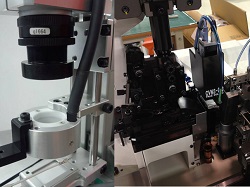

This system sets a camera on the cable feeding route in an automatic crimping machine and inspects all crimped terminals. Without stopping feeding, you can capture clear images with a high shutter speed camera in the feeding speed of 2m/sec.

We used to finally depend on human eye to detect the following defects, however this system can detect those defects by using images.

- Insulation barrel errors

- One strand out

- Low conductor

- High insulation

- Seal insert errors (seal positions, cut seal, reversed insert, etc.)

We are struggling for more man-power saving in a total inspection.

The software is designed exclusively for inspecting crimped terminals. Therefore even operators who are not accustomed to the image processing software can also operate it easily. For example, set the frames on measurement parts in an image captured by a camera. If several good samples are learned in the teach-in mode, you can begin to perform the inspection soon.

Features:

- The high shutter speed camera is set on the cable route in the automatic crimping machine. The space-saving optical system is not influenced by external light noise.

- It inspects stripped wires on the forward path with an additional LED light and crimped terminals on the return path.

- It is designed to learn up to 300 good samples. The unique averaging process removes small variations among good samples to detect only defects.